Photonics Online on PhotoScribe Launching an Upgraded LMS-650XS Laser for Optical Components ID Marking

July 13, 2016

See the original article on Photonics Online.

With high precision, PhotoScribe Technologies is making optical identification and tracking capabilities effortless with its LMS-650 and 650XS lasers.

PhotoScribe Technologies has upgraded their LMS Laser systems to release their LMS-650XS as an exceptional laser solution for optical component ID marking for traceability. This laser incorporates a high precision motion system with submicron accuracy, making it perfectly suited for micro-optic marking applications.

Glass and plastic are largely transparent to laser light falling into the 200nm UV spectrum. The LMS-650XS utilizes a 193nm Excimer technology which is needed for surface absorption in order to address and mark a broad range of optical materials.

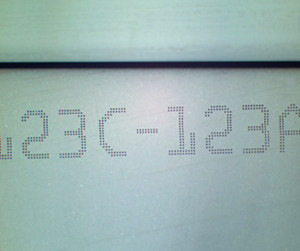

Ideal for optical component marking the lasers can be used to create a fiducial mark, determining the area of transition in optical lenses and eyewear. In addition, efficient unique ID marking is increasingly important for tracing the product through the life cycle. With the LMS-650XS ID marking lenses can be tracked back to the equipment level, identifying and sorting defects, minimizing loss of time and effort when problems arise. In addition, optical components can be marked for brand recognition as well.

A stress-free, photo ablative, non-thermal process, cold excimer laser marking will not impact optic performance, nor will it negatively affect any coating on a lens.

Often today, a pencil is used to mark the direction of lens coating, which would otherwise be hard or impossible to identify in the field. However, this is not a permanent mark; it is hard to read and not suitable for micro-optics. The LMS-650XS laser renders the entire process permanent, simple and stress-free.

With a practical design, the laser is compact enough to fit on any tabletop. The high precision stage has been upgraded by doubling its mark speed, while ensuring that accuracy and high-resolution are unaffected.

David Benderly, CEO of PhotoScribe, says, “Our Company specializes in manufacturing lasers for transparent, brittle, thermally sensitive and hard to mark substrates. With a focus on micro-marking, our LMS-650 product line is uniquely compatible for marking the growing market of micro-optics.”

In addition to the LMS-650’s high performance, PhotoScribe Technologies works to provide safety and fast response support, alongside easy process integration.