PhotoScribe’s Laser Series

We offer three laser series specifically designed for natural and lab-grown diamonds as well as other gemstones. All of our lasers can be customized in order to fit your individual needs and specifications. For more information, schedule your free consultation today.

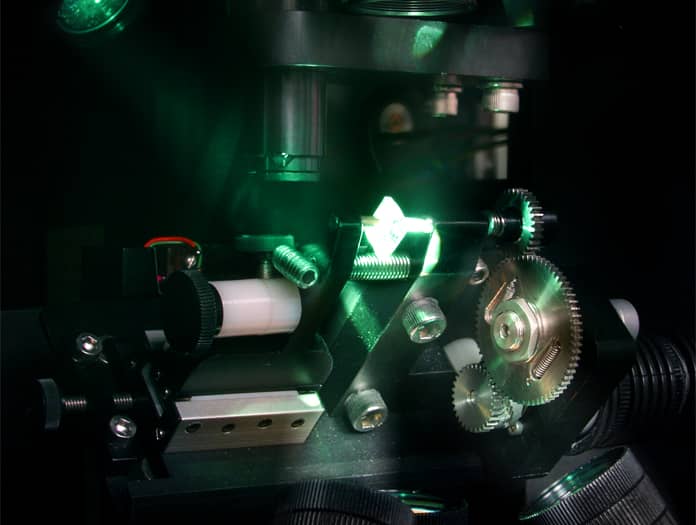

LMS SurfaceScribe™ Series

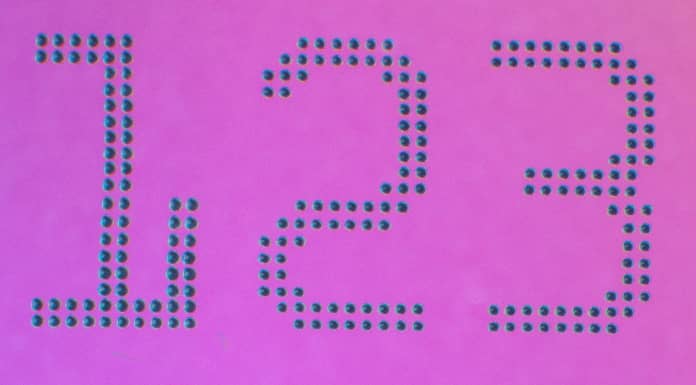

The LMS series provides the only commercially available cold lasers designed and optimized for the diamond industry. Cold lasers do not require pre and post-treatment, saving time and simplifying the marking process resulting in a precise mark with no damage to the stone. With high-contrast SurfaceScribe™ markings, these lasers inscribe both invisible and visible identifiers. Used by the industry’s leading labs and brands, the LMS series marks certification numbers, security marks, brand names, logos, photographs and more. The laser series is known for providing high-precision motion with extreme accuracy.

LMFT PermaScribe™ Series

Our LMFT PermaScribe™ laser provides a sub-surface inscription that can be visible or invisible under 10X magnification and inscribed on any area of the faceted diamond. This provides an extra level of protection by preventing the removal of the mark without dramatically altering the stone. The laser is part of solutions for diamond provenance, journey, identification, branding, supply chain security, personalization and more.

LMP Pico Cool Series

The LMP Pico Cool lasers are short pulse-duration systems used for the micro-machining and processing of diamonds. Available in several wavelengths, it’s considered a more affordable option to our LMFT PermaScribe™ laser for subsurface inscription.

MVBR-250 Micro Barcode Reader

Until now, the only way to read micro-scale barcodes was with a barcode reader mounted on a microscope, presenting many limitations. Our MVBR-250 a pen-like Micro Barcode Reader is optimized to read 2D barcodes ranging in size from 50 microns to a few millimeters and can easily be brought to larger objects for ease of viewing. The machine-vision based software compensates for mark distortion, low contrast, and non-uniformity. It comes with a USB, with no additional power supply needed.